Boeing 737 Engine Start: A Comprehensive Guide

Ever wondered about the orchestrated dance of power and precision that brings a Boeing 737 to life? The process of starting a 737's engines is more than just flipping a switch; it's a carefully sequenced procedure crucial for safe and efficient flight. This guide provides a comprehensive look into the fascinating world of Boeing 737 engine starts.

Imagine standing on the tarmac, the sheer size of the aircraft looming large. Within its wings reside complex turbofan engines, each a marvel of engineering. Initiating these engines requires understanding the interplay of various systems, from fuel supply to electrical power. This understanding is paramount not only for pilots but also for anyone fascinated by the mechanics of flight.

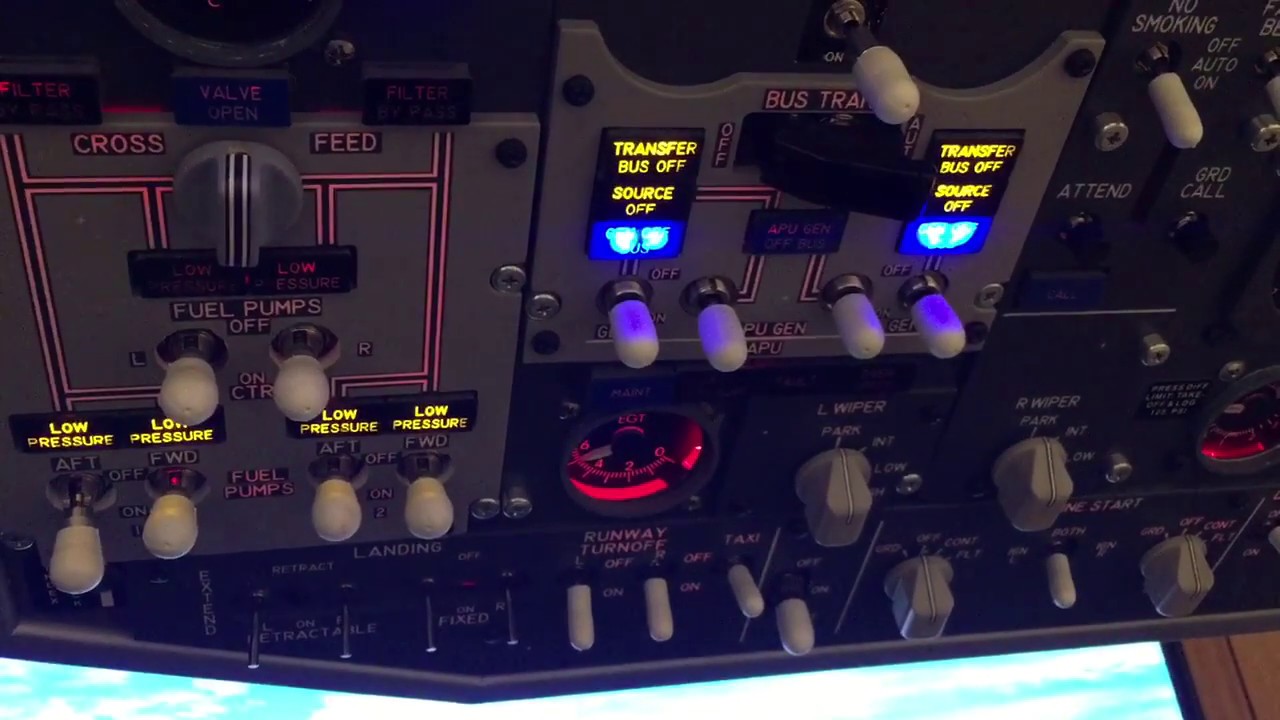

The journey of starting a 737 engine begins with the APU (Auxiliary Power Unit), a small turbine engine usually located in the tail. The APU provides the initial electrical power and bleed air needed to power the aircraft's systems and initiate the main engines. This is a fundamental step, setting the stage for the main event - the engine start sequence itself.

The Boeing 737, a stalwart of the aviation industry, has a rich history of engine development. From early low-bypass turbofans to the modern high-bypass CFM56 and LEAP engines, the technology has continuously evolved for improved fuel efficiency, reduced noise, and enhanced reliability. Each generation of engines brings with it specific start procedures, showcasing the continuous advancements in aerospace engineering.

Understanding the process is crucial for ensuring a smooth and safe engine start. Incorrect procedures can lead to issues such as hot starts, hung starts, or even engine damage. A successful engine start requires careful monitoring of engine parameters like EGT (Exhaust Gas Temperature), N1 (fan speed), and N2 (compressor speed). These parameters provide crucial feedback on the engine's health during the start sequence.

The history of starting jet engines on the Boeing 737 traces back to the aircraft's initial design in the 1960s. Early models utilized pneumatic starters powered by compressed air. With advancements in technology, the more efficient electric starters became the standard. The evolution of engine start systems reflects the broader trend of improving reliability and reducing reliance on external systems.

The importance of a correct engine start cannot be overstated. A successful start ensures a safe and timely departure, minimizing delays and maximizing operational efficiency. Proper engine start procedures are vital for preventing engine damage, which can be costly and time-consuming to repair. Moreover, a smooth engine start contributes to a quieter airport environment, reducing noise pollution for surrounding communities.

One of the key elements in a Boeing 737 engine start is the ignition system. This system provides the initial spark that ignites the fuel-air mixture in the combustion chamber. Another essential component is the fuel control unit, which regulates the fuel flow to the engine during the start sequence. The harmonious interaction of these systems, along with the starter motor, ensures a successful and efficient engine start.

Advantages and Disadvantages of Understanding 737 Engine Starts

| Advantages | Disadvantages |

|---|---|

| Enhanced safety awareness | Requires dedicated study and learning |

| Deeper appreciation of aviation technology | Access to detailed information might be limited for non-professionals |

| Improved understanding of flight operations |

Successfully starting a Boeing 737 engine provides numerous benefits. First and foremost, it enables the aircraft to take off and fulfill its primary function of transportation. A properly started engine contributes to fuel efficiency, minimizing fuel consumption during taxi and takeoff. Furthermore, a smooth engine start reduces noise pollution, benefiting both passengers and the surrounding environment.

Frequently Asked Questions:

1. What is the role of the APU in starting the engines? The APU provides initial power and bleed air.

2. What are N1 and N2? These represent the fan and compressor speeds respectively.

3. What is a hot start? A hot start occurs when the EGT exceeds safe limits during the start.

4. What is a hung start? This occurs when the engine starts but fails to reach idle speed.

5. How is the fuel flow controlled during the start? The fuel control unit regulates the fuel flow.

6. What is the function of the ignition system? It provides the initial spark to ignite the fuel-air mixture.

7. Why is monitoring EGT important? It ensures the engine is operating within safe temperature limits.

8. How have engine start systems evolved? From pneumatic to more efficient electric starters.

Understanding the intricacies of starting a Boeing 737 engine provides a deeper appreciation for the complex systems that power these magnificent machines. From the initial engagement of the starter to the roar of the engines reaching idle power, the start sequence is a testament to human ingenuity. This knowledge enhances our understanding of aviation, safety, and the technological marvels that enable flight. This guide is a starting point for further exploration, encouraging readers to delve deeper into the fascinating world of aviation technology. The future of aviation continues to evolve, and understanding the fundamentals of engine operations is crucial for both professionals and enthusiasts alike.

Unlocking the power of the mercury 99 pro kicker outboard motor

Conquering the terrain a deep dive into the used toyota sequoia trd

The quirky world of animated potatoes