Decoding Hydraulic Motor Schematics: A Deep Dive

Ever stared at a hydraulic system diagram and felt like you were deciphering ancient hieroglyphs? Don't worry, you're not alone. Understanding hydraulic motor schematic symbols is crucial for anyone working with fluid power systems, from engineers designing complex machinery to technicians troubleshooting on the shop floor. These symbols are the language of hydraulics, providing a concise and standardized way to represent the various components within a system. Let's dive into this fascinating world and unlock the secrets of these powerful little pictograms.

Hydraulic motor representation in schematics isn't arbitrary. Each symbol, a carefully crafted graphic, conveys a wealth of information about the motor's type, function, and connection points. Imagine trying to understand a complex hydraulic system without these visual cues. It would be like trying to read a book with all the words scrambled. These symbols bring order to the chaos, enabling engineers and technicians to communicate effectively and troubleshoot efficiently.

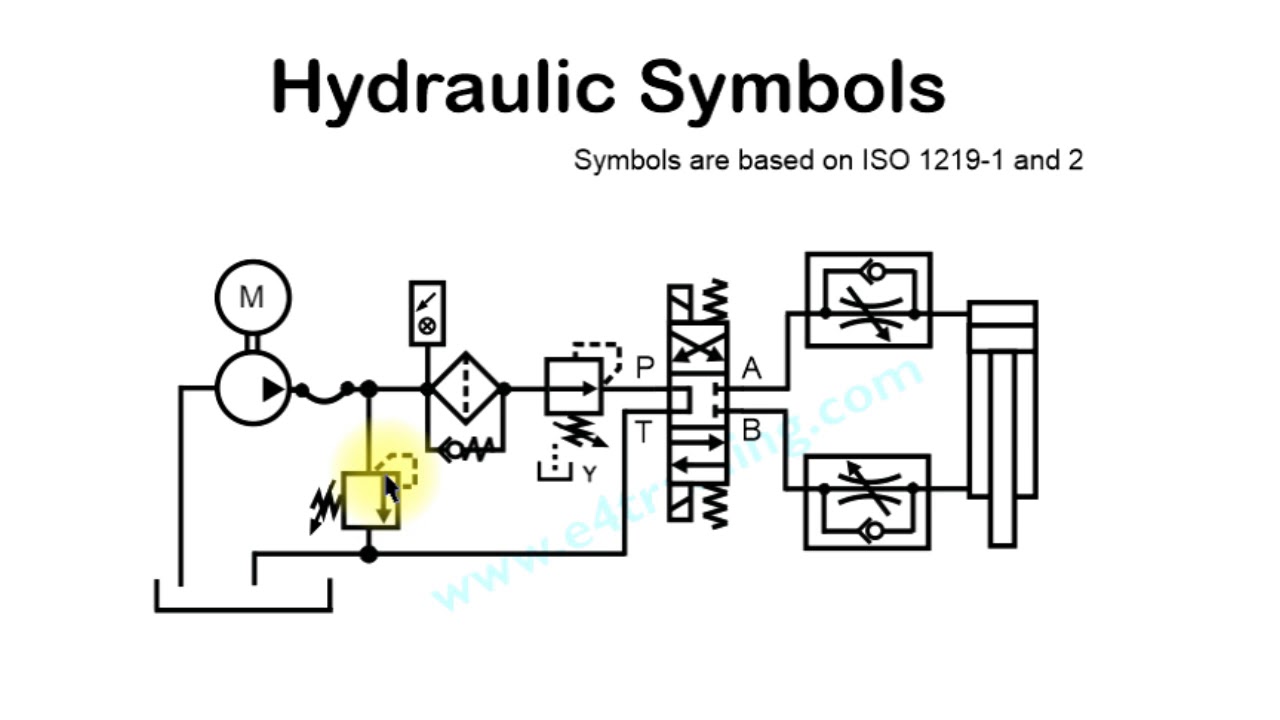

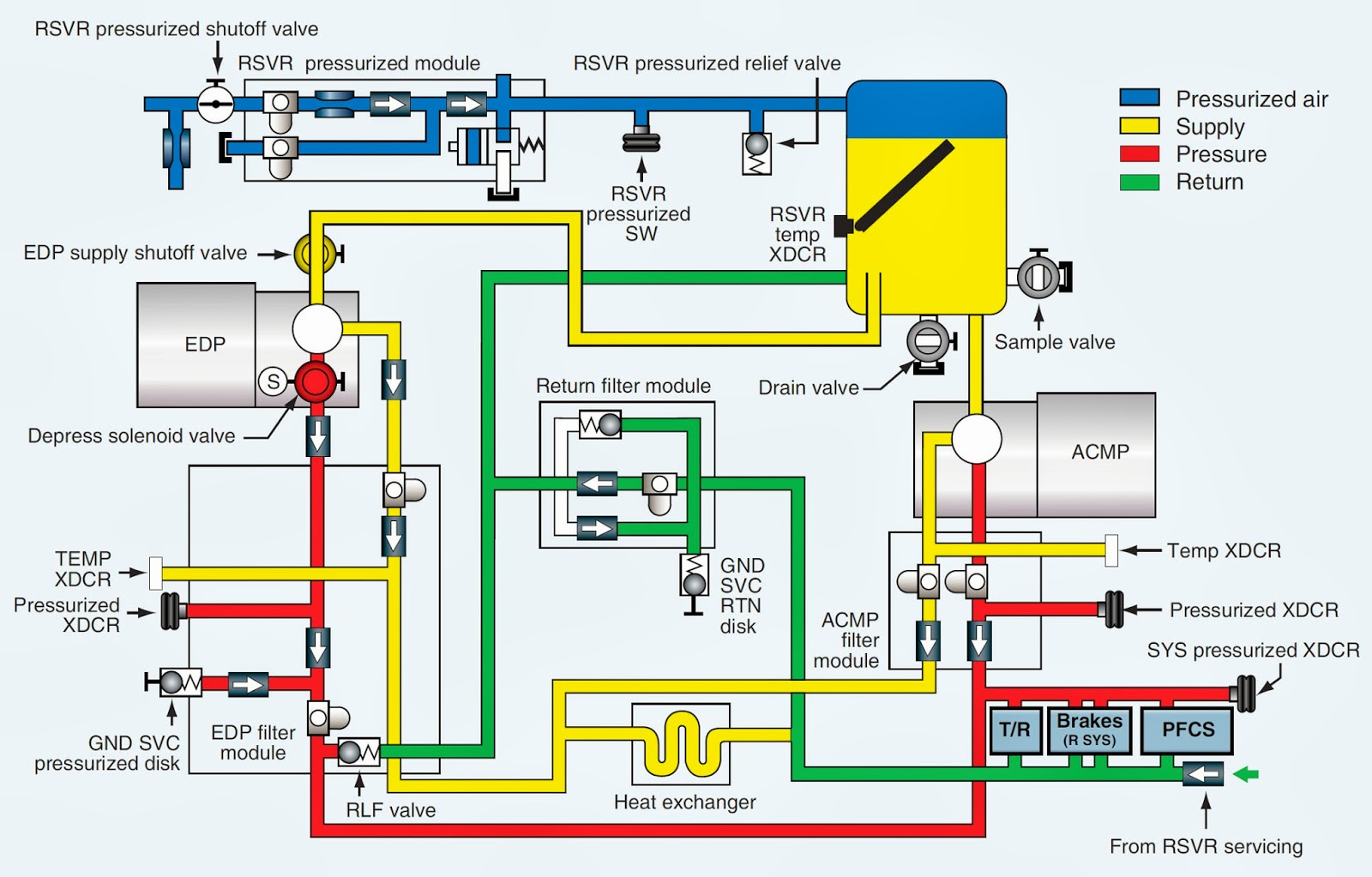

The history of hydraulic schematic symbols is intertwined with the development of hydraulics itself. As hydraulic systems became more complex, the need for a standardized visual language became increasingly apparent. Early schematics might have been crude drawings, but over time, organizations like ISO and ANSI developed standardized symbols, ensuring clarity and consistency across different industries and geographical regions. This standardization is vital, allowing engineers from different backgrounds to understand and collaborate on hydraulic projects seamlessly.

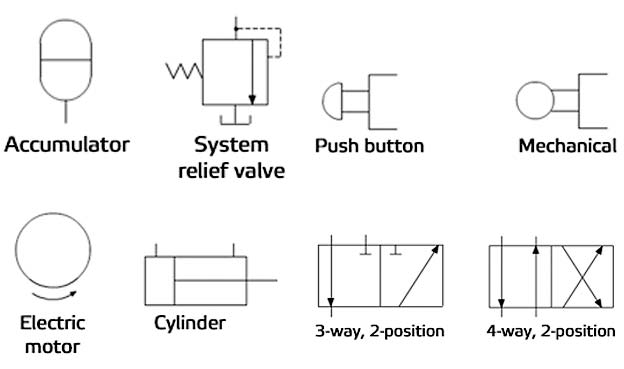

The core function of a hydraulic motor schematic representation is to simplify complex systems. By reducing a physical motor to a symbolic representation, engineers can focus on the overall system design and functionality without getting bogged down in minute details. These symbols represent different types of hydraulic motors, including fixed displacement, variable displacement, and bidirectional motors, each with its unique visual identifier. Understanding these subtle differences is crucial for proper system design and maintenance.

Issues related to incorrect interpretation of hydraulic motor symbols can have significant consequences, leading to system malfunctions, safety hazards, and costly repairs. Misinterpreting a symbol for a unidirectional motor as a bidirectional one, for instance, can lead to unexpected movements and potential damage to equipment. That's why accurate and consistent use of these symbols is paramount in the world of hydraulics.

A basic hydraulic motor symbol typically resembles a circle with an arrow indicating the direction of rotation. Variations in the symbol, such as adding a slanted arrow or a double arrow, indicate different motor functionalities. For example, a fixed displacement motor is represented by a circle with a single arrow, while a variable displacement motor might have an arrow with a slanted line through it.

One benefit of using standardized hydraulic symbols is improved communication. Engineers and technicians across the globe can understand the same schematic, fostering collaboration and reducing errors.

Another advantage is streamlined troubleshooting. Identifying faulty components becomes easier when the entire system is laid out clearly in a schematic.

Finally, standardized symbols contribute to better system design. By visualizing the entire hydraulic circuit, engineers can optimize performance and identify potential issues before they become real-world problems.

Advantages and Disadvantages of Standardized Hydraulic Motor Symbols

| Advantages | Disadvantages |

|---|---|

| Clear Communication | Requires Training to Understand |

| Efficient Troubleshooting | Potential for Misinterpretation if not used correctly |

| Improved System Design | Limited Detail in Basic Symbols |

Best Practice 1: Always consult the relevant ISO or ANSI standard for the correct symbols.

Best Practice 2: Ensure consistency in symbol usage throughout the schematic.

Best Practice 3: Clearly label all components and connections.

Best Practice 4: Use software tools designed for creating hydraulic schematics.

Best Practice 5: Regularly review and update schematics as needed.

FAQ 1: What does a circle with an arrow inside represent in a hydraulic schematic? A: A hydraulic motor.

FAQ 2: How is a variable displacement motor represented? A: Often with a modified arrow within the circle.

FAQ 3: Where can I find standardized hydraulic symbols? A: ISO and ANSI standards.

FAQ 4: Why is it important to use standardized symbols? A: For clear communication and accurate system design.

FAQ 5: What can happen if symbols are misinterpreted? A: System malfunctions and safety hazards.

FAQ 6: How can I learn more about hydraulic schematic symbols? A: Through specialized training courses and reference materials.

FAQ 7: Are there software tools for creating hydraulic schematics? A: Yes, several software packages are available.

FAQ 8: How often should hydraulic schematics be reviewed? A: Regularly, especially after any system modifications.

One trick for interpreting hydraulic motor schematic symbols is to pay close attention to the arrow's direction, which indicates the motor's rotation. Another tip is to cross-reference the symbol with the component list to ensure accurate identification.

In conclusion, understanding hydraulic motor schematic symbols is essential for anyone working with hydraulic systems. These seemingly simple symbols are a powerful tool for communication, troubleshooting, and design. By mastering the language of hydraulics, engineers and technicians can ensure the safe and efficient operation of complex fluid power systems. From their historical development to their practical applications, hydraulic schematic symbols play a crucial role in the world of fluid power. Investing time in learning and understanding these symbols is an investment in your professional development and the overall success of your hydraulic projects. Embrace the power of these visual cues and unlock the potential of fluid power technology. Continuously updating your knowledge about these symbols and best practices ensures you remain at the forefront of hydraulic system design and maintenance. Dive deeper into the specifics of each symbol, practice interpreting complex schematics, and you'll become fluent in the language of hydraulics, empowering you to design, troubleshoot, and maintain fluid power systems with confidence.

Unveiling the vast player base of ea fc 24

The chilling reign of mccarthyism understanding a dark chapter in american history

Unlock savings with doordash canada promo codes