Mastering the M27 Engine Timing Sensor: A Comprehensive Guide

Is your engine running rough? Does it hesitate or stall unexpectedly? The culprit might be a small but critical component: the engine timing sensor. In engines like the M27, this sensor plays a vital role in ensuring smooth and efficient operation. This comprehensive guide will delve into the intricacies of the M27 engine timing sensor, exploring its functionality, common issues, and best practices for maintenance.

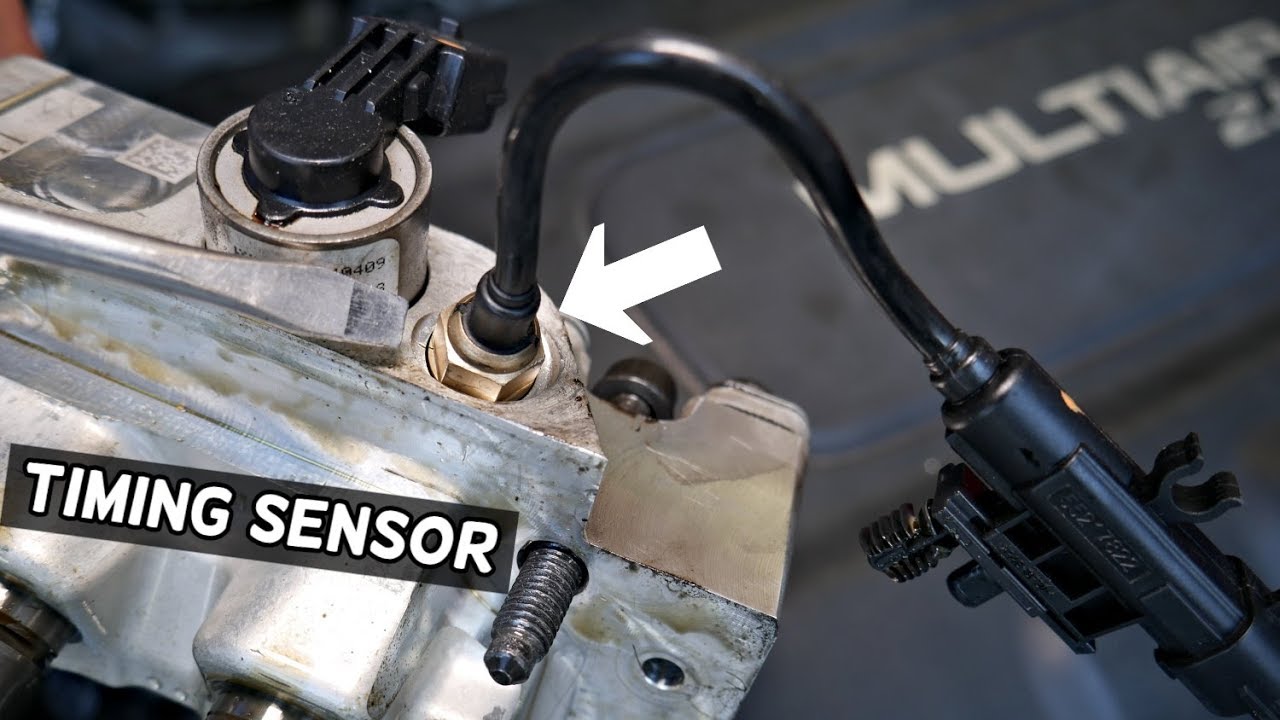

The engine timing sensor, sometimes referred to as the camshaft position sensor or crankshaft position sensor depending on its specific role in the M27 engine, acts as the engine's "eyes" for timing. It monitors the rotation of the crankshaft and/or camshaft, sending precise signals to the engine control unit (ECU). This information allows the ECU to determine the exact position of the pistons and valves, enabling it to accurately time fuel injection and ignition.

The development of the engine timing sensor, much like other electronic engine management components, arose from the need for increased efficiency and reduced emissions. Early engines relied on mechanical systems for timing, which were less precise and adaptable. The advent of electronic engine control systems and sensors like the M27's timing sensor allowed for much finer control, leading to improved fuel economy, lower emissions, and smoother engine performance. The precise origins of the M27 engine's specific timing sensor are likely tied to the engine's development and manufacturer, but the overall trend towards electronic engine management makes its inclusion a natural progression.

The importance of a properly functioning M27 timing sensor cannot be overstated. A faulty sensor can lead to a range of problems, from rough idling and poor fuel economy to complete engine failure. When the ECU doesn't receive accurate timing information, it can't correctly manage fuel injection and ignition. This can result in misfires, reduced power, and increased emissions. In severe cases, a malfunctioning timing sensor can prevent the engine from starting altogether.

Common issues related to the M27 engine timing sensor often include wiring problems, sensor damage, or contamination. Loose or corroded wiring can disrupt the signal between the sensor and the ECU. Physical damage to the sensor itself, perhaps due to impact or wear and tear, can also cause malfunctions. Finally, contamination from oil or debris can interfere with the sensor's ability to accurately detect engine position. Troubleshooting these issues often involves inspecting the wiring, testing the sensor's resistance, and replacing the sensor if necessary.

Benefits of a functioning M27 Engine timing sensor include: optimal fuel efficiency, reduced emissions, and smooth engine operation.

If you suspect an issue with your M27's timing sensor, a qualified mechanic should diagnose and address the problem. They possess the necessary tools and expertise to accurately pinpoint the cause of the malfunction. Replacement of the sensor is usually straightforward, but proper installation and calibration are crucial for optimal performance.

Advantages and Disadvantages of Engine Timing Sensor M27

Information on specific advantages and disadvantages of the M27 engine timing sensor are not readily available publicly. However, the general advantages and disadvantages of engine timing sensors apply:

Troubleshooting typically involves checking error codes, inspecting wiring, and testing sensor output. A multimeter can be used to measure the sensor's resistance and voltage.

Frequently Asked Questions about Engine Timing Sensors:

1. What does the engine timing sensor do? It tells the ECU the position of the crankshaft/camshaft for precise timing of fuel injection and ignition.

2. What are the symptoms of a bad engine timing sensor? Rough idling, misfires, poor fuel economy, difficulty starting.

3. How is the engine timing sensor diagnosed? Through error code scanning, wiring inspection, and sensor testing.

4. Can I replace the engine timing sensor myself? Yes, but it requires some mechanical aptitude and the correct tools.

5. How much does an engine timing sensor cost? Prices vary depending on the make and model of the vehicle.

6. How long does an engine timing sensor last? Typically, many years, but they can fail prematurely due to various factors.

7. What causes an engine timing sensor to fail? Wiring problems, sensor damage, or contamination.

8. Can a bad engine timing sensor cause serious engine damage? Yes, if left unaddressed, it can lead to further engine problems.

Tips and tricks related to working with engine timing sensors include ensuring cleanliness during installation and handling the sensor with care to avoid damage. Consulting your vehicle's service manual is highly recommended for specific instructions and precautions.

In conclusion, the M27 engine timing sensor, although a small component, plays a pivotal role in the smooth and efficient operation of the engine. Its accurate reporting of crankshaft/camshaft position allows the ECU to precisely manage fuel injection and ignition, leading to optimized performance, fuel efficiency, and reduced emissions. Understanding the function, potential issues, and maintenance of the M27's timing sensor is crucial for any owner or mechanic. By staying informed and proactive, you can ensure the longevity and reliability of your engine. Neglecting this critical component can lead to significant performance problems and potentially costly repairs. Regular maintenance and prompt attention to any warning signs will keep your M27 engine running smoothly for years to come. Invest in the health of your engine by understanding and caring for its essential components like the timing sensor.

Unlock the secrets of fly tying master tutorials and patterns

Essential premarital questions for a strong foundation

Decoding the mercedes sprinter van lug pattern your guide to wheel fitment