Safety Shut Off Switches: Your Ultimate Guide

Imagine a world without the ability to instantly stop a machine in an emergency. Picture a runaway conveyor belt, a malfunctioning power tool, or an overheating engine, all lacking that crucial emergency stop. This is where the often-overlooked safety shut off switch becomes a silent guardian, preventing accidents and mitigating potential disasters.

Safety shut off switches, also known as emergency stop switches or kill switches, are essential safety devices designed to quickly de-energize equipment or machinery in hazardous situations. They provide a rapid means of disconnecting power to prevent injury to personnel or damage to equipment. From industrial settings to household appliances, these seemingly simple mechanisms play a critical role in maintaining safety and preventing catastrophic incidents.

The history of the safety shut off switch is interwoven with the rise of industrial machinery. As complex machines became commonplace, so too did the need for a reliable way to quickly stop them in emergencies. Early iterations were often rudimentary, involving manual levers or disconnects. However, as technology advanced, so did the sophistication of these devices, evolving into the robust and standardized systems we rely on today.

The importance of these emergency stop mechanisms cannot be overstated. They are the last line of defense against accidents, providing a critical layer of protection for workers and equipment alike. By enabling immediate cessation of operation, they mitigate risks and minimize the potential for serious harm. Their presence often dictates compliance with safety regulations and standards across various industries.

However, simply having a safety shut off mechanism isn't enough. Issues can arise from improper installation, lack of maintenance, or inadequate training on their use. A poorly placed emergency stop button, a switch that's difficult to access in an emergency, or employees unfamiliar with its location can render the device ineffective. Regular inspection and testing are crucial to ensure these switches remain functional and reliable when needed most.

A safety shut off switch, in its simplest form, is a device that interrupts the flow of power to a machine. This can be achieved through a variety of mechanisms, from simple mechanical breaks to complex electronic circuits. For example, a push-button emergency stop on a power tool cuts off the electrical current, bringing the tool to an immediate halt. Similarly, a safety shut off valve on a gas line can quickly stop the flow of gas in the event of a leak.

There are numerous benefits to incorporating safety shut off switches. First, they prevent injuries by allowing for quick reactions in hazardous situations. Second, they minimize equipment damage by stopping a malfunctioning machine before it can cause extensive harm. Third, they contribute to a safer work environment, promoting peace of mind among employees and reducing the risk of accidents.

Implementing an effective safety shut off system requires careful planning. First, identify all hazardous machinery and processes. Next, select appropriate shut off devices for each piece of equipment. Ensure the switches are easily accessible and clearly marked. Finally, train all personnel on the proper use and location of these devices.

Advantages and Disadvantages of Safety Shut Off Switches

| Advantages | Disadvantages |

|---|---|

| Prevents injuries | Can be costly to implement |

| Minimizes equipment damage | Requires regular maintenance |

| Improves safety culture | Can be accidentally triggered |

Best practices for implementing safety shut off switches include regular testing and inspection, clear labeling and signage, employee training, proper placement for easy access, and using robust, reliable devices.

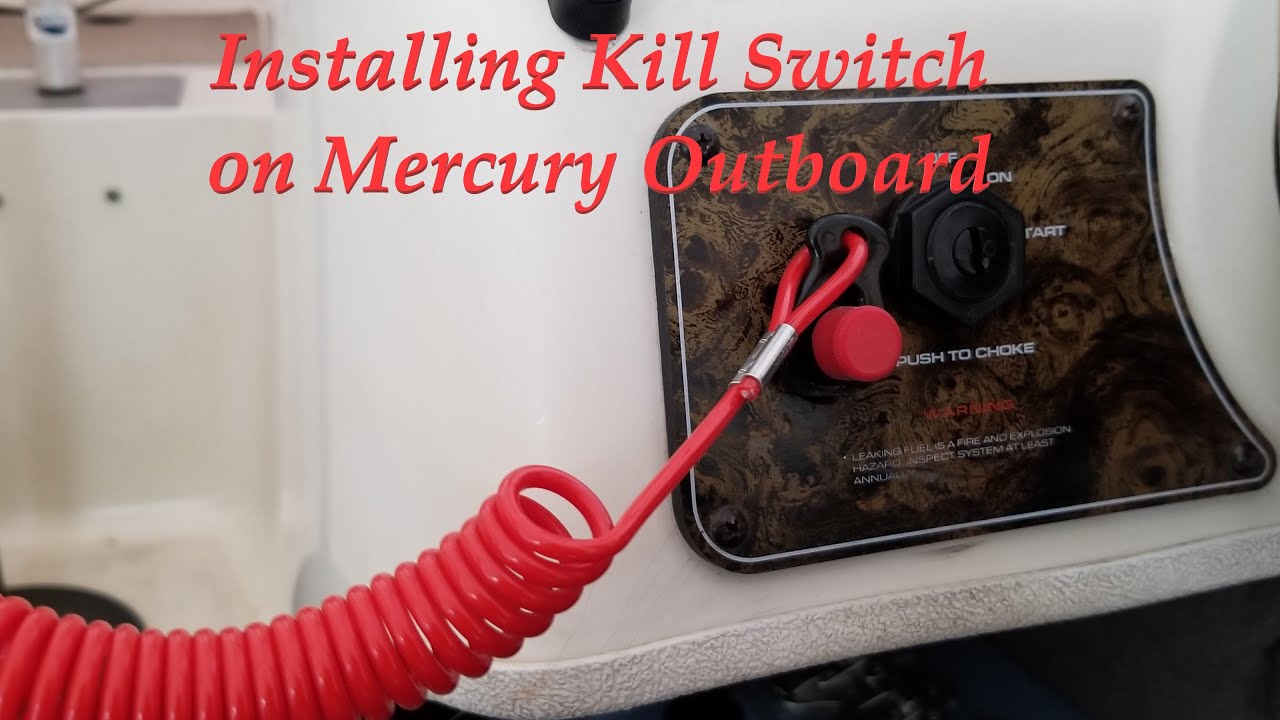

Real-world examples include emergency stops on assembly lines, kill switches on boats, safety shut off valves on gas appliances, emergency brakes on trains, and shut down systems for nuclear reactors.

Challenges related to safety shut off switches include ensuring proper placement, preventing accidental activation, maintaining functionality, training employees, and selecting appropriate devices. Solutions include clear labeling, robust switch design, regular testing, comprehensive training programs, and expert consultation.

Frequently Asked Questions:

1. What is a safety shut off switch? - A device designed to quickly de-energize equipment in hazardous situations.

2. Why are they important? - They prevent injuries and minimize equipment damage.

3. What are some examples? - Emergency stops on machinery, kill switches on boats, and safety valves on gas lines.

4. How do they work? - They interrupt the flow of power to a machine.

5. Where should they be located? - Easily accessible and clearly marked.

6. How often should they be tested? - Regularly, according to industry standards.

7. Who is responsible for their maintenance? - Trained personnel.

8. What type of training is required? - Comprehensive training on proper use and location.

Tips and tricks related to safety shut off switches include using color-coded labels, implementing lockout/tagout procedures, and conducting regular drills to ensure employees are familiar with their use.

In conclusion, the safety shut off switch, while often unassuming, is a critical component of safety systems across a wide range of applications. From preventing workplace injuries to mitigating industrial disasters, these devices play a vital role in protecting both people and property. By understanding their history, importance, and proper implementation, we can ensure their effectiveness and contribute to a safer world. Regular maintenance, thorough training, and adherence to best practices are essential to maximizing the benefits of these critical safety devices. It's not just about having a safety shut off switch; it's about ensuring it's always ready to perform its life-saving function. Make safety a priority, and invest the time and resources needed to keep your safety shut off switches in optimal working condition. Your safety and the safety of those around you depend on it.

Printable christmas window decorations festive holiday cheer

Conquer any terrain your guide to the f 150 tremor build and price

Snooze sanctuary behr bedroom colors that dont suck

.jpg)