Troubleshooting Your Ford 3000 Starter

Is your Ford 3000 tractor refusing to turn over? A common culprit behind starting problems is the starter solenoid wiring. Understanding this system is crucial for any Ford 3000 owner. This guide provides a comprehensive overview of the Ford 3000 starter solenoid wiring, helping you diagnose and troubleshoot issues effectively.

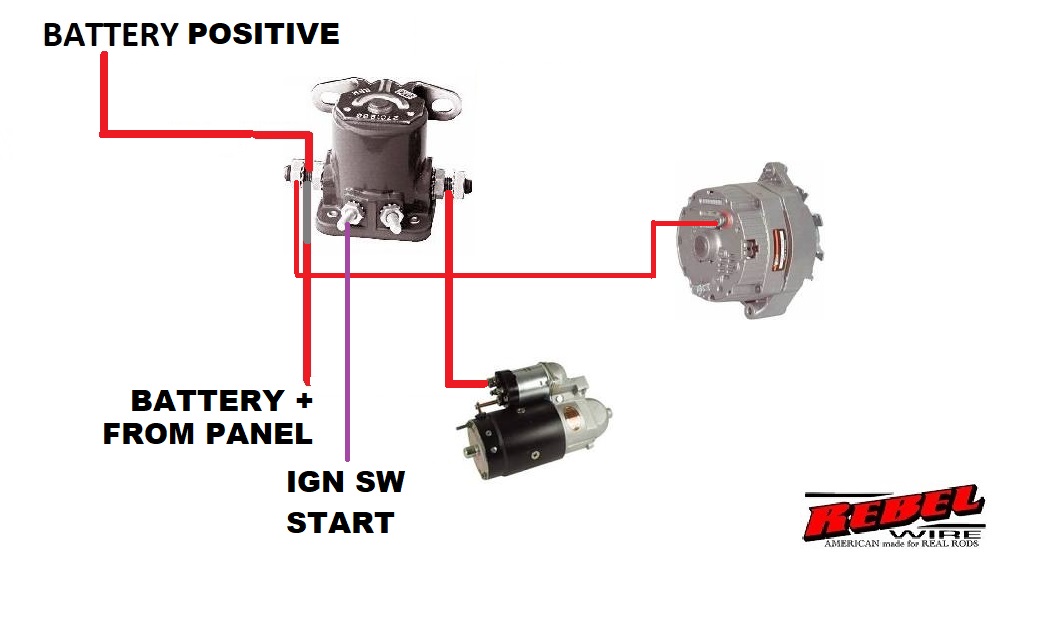

The starter solenoid acts as a relay, controlling the high current needed to engage the starter motor. It receives a small current signal from the ignition switch, which then activates a larger circuit to power the starter. A malfunctioning solenoid or faulty wiring can leave you stranded.

The Ford 3000, a workhorse tractor produced for many years, has a relatively simple starter solenoid wiring setup. However, age, wear, and environmental factors can contribute to wiring degradation and connection problems. This can manifest as clicking sounds from the solenoid, a slow-cranking engine, or even a complete failure to start.

This article will cover the basics of the Ford 3000 starter circuit, common wiring issues, troubleshooting steps, and preventative maintenance tips. By understanding how the system works, you'll be better equipped to handle starting problems and keep your tractor running smoothly.

Before diving into the specifics, it's essential to have a basic understanding of electrical principles and safety precautions. Always disconnect the battery's negative terminal before working on any electrical components to prevent shocks and short circuits. A wiring diagram specific to your Ford 3000 model year is also invaluable for tracing wires and identifying connections.

The Ford 3000 starter solenoid wiring hasn't changed dramatically over the years. The basic principle remains the same: a small control wire from the ignition switch energizes the solenoid, which then closes a high-current circuit to the starter motor. Understanding this fundamental process is key to effective troubleshooting.

Common issues with Ford 3000 starter solenoid wiring include corroded connections, loose or broken wires, a faulty solenoid itself, and problems with the ignition switch. Corroded connections can interrupt the flow of electricity, while loose or broken wires can prevent the solenoid from receiving the signal to engage.

One benefit of a properly functioning Ford 3000 starter solenoid wiring system is reliable starting. A strong, consistent start is essential for getting your tractor up and running quickly. Another benefit is extended starter motor life. The solenoid protects the starter motor from excessive wear by controlling the current flow. Finally, understanding the wiring allows for easier diagnostics and repair. When problems arise, knowing how the system works simplifies troubleshooting and saves you time and money.

If you suspect a problem with your Ford 3000's starter solenoid wiring, begin by visually inspecting the solenoid and its connections for corrosion, loose wires, or damage. Clean any corroded connections with a wire brush or sandpaper. Tighten any loose connections. If the problem persists, test the solenoid using a multimeter to check for continuity and proper voltage. A wiring diagram will help you identify the correct terminals to test.

Advantages and Disadvantages of a Well-Maintained Starter System

| Advantages | Disadvantages |

|---|---|

| Reliable starting | Requires periodic inspection and maintenance |

| Extended starter motor life | Can be affected by environmental factors like moisture and corrosion |

| Simplified troubleshooting | Requires basic electrical knowledge for DIY repairs |

Best practices for maintaining your Ford 3000 starter solenoid wiring include regularly inspecting connections for corrosion, keeping the battery terminals clean, and protecting the wiring from damage. Applying dielectric grease to connections can help prevent corrosion. Securing loose wires with zip ties can minimize vibration and breakage. Replacing worn or damaged wires promptly can prevent further issues.

Frequently asked questions about Ford 3000 starter solenoid wiring include: Why is my solenoid clicking? (Possible causes: low battery voltage, bad solenoid, corroded connections). Why won't my tractor start? (Possible causes: faulty ignition switch, bad starter motor, wiring issues). How do I test the solenoid? (Use a multimeter to check for continuity and voltage).

A tip for troubleshooting starter issues: always start with the simplest solution first, such as checking the battery and connections. Often, a simple cleaning or tightening can resolve the problem. Another trick is to use a remote starter switch to bypass the ignition switch and test the solenoid directly.

In conclusion, understanding your Ford 3000 starter solenoid wiring is essential for maintaining the reliable operation of your tractor. By familiarizing yourself with the system, common issues, and troubleshooting steps, you can address starting problems quickly and efficiently. Regularly inspecting and maintaining the wiring can prevent future issues and ensure your Ford 3000 starts reliably for years to come. This knowledge empowers you to tackle these challenges head-on, saving you time and money in the long run. Don't let starting problems keep you from getting your work done – take the time to understand your Ford 3000's electrical system, and you'll be well-equipped to handle any starting challenge that comes your way.

Decoding gangsta boos lyrical legacy influence impact evolution

Refreshing spaces with sherwin williams new white paint

Enchanting elf names for your dd 5e character