Unlocking Electrical Safety The Crucial Role of Hipot Testing

Imagine plugging in your brand new, shiny toaster, excited for that perfectly crisp slice of sourdough. But instead of toasty goodness, you're met with sparks, a tripped breaker, or worse. This nightmare scenario highlights why electrical safety is paramount. And it's where hipot testing, also known as dielectric withstand testing, steps into the spotlight.

The fundamental purpose of hipot testing is to verify the insulation integrity of electrical equipment and systems. It's a critical safety check to ensure they can withstand voltage surges without breaking down and causing harm. Think of it as a stress test for your electrical devices, pushing them to their limits in a controlled environment to prevent real-world disasters.

Why is this so important? Because a failure in electrical insulation can lead to dangerous shocks, equipment damage, and even fires. Hipot testing acts as a gatekeeper, preventing faulty products from reaching consumers and ensuring the safety of everyone who interacts with electrical systems.

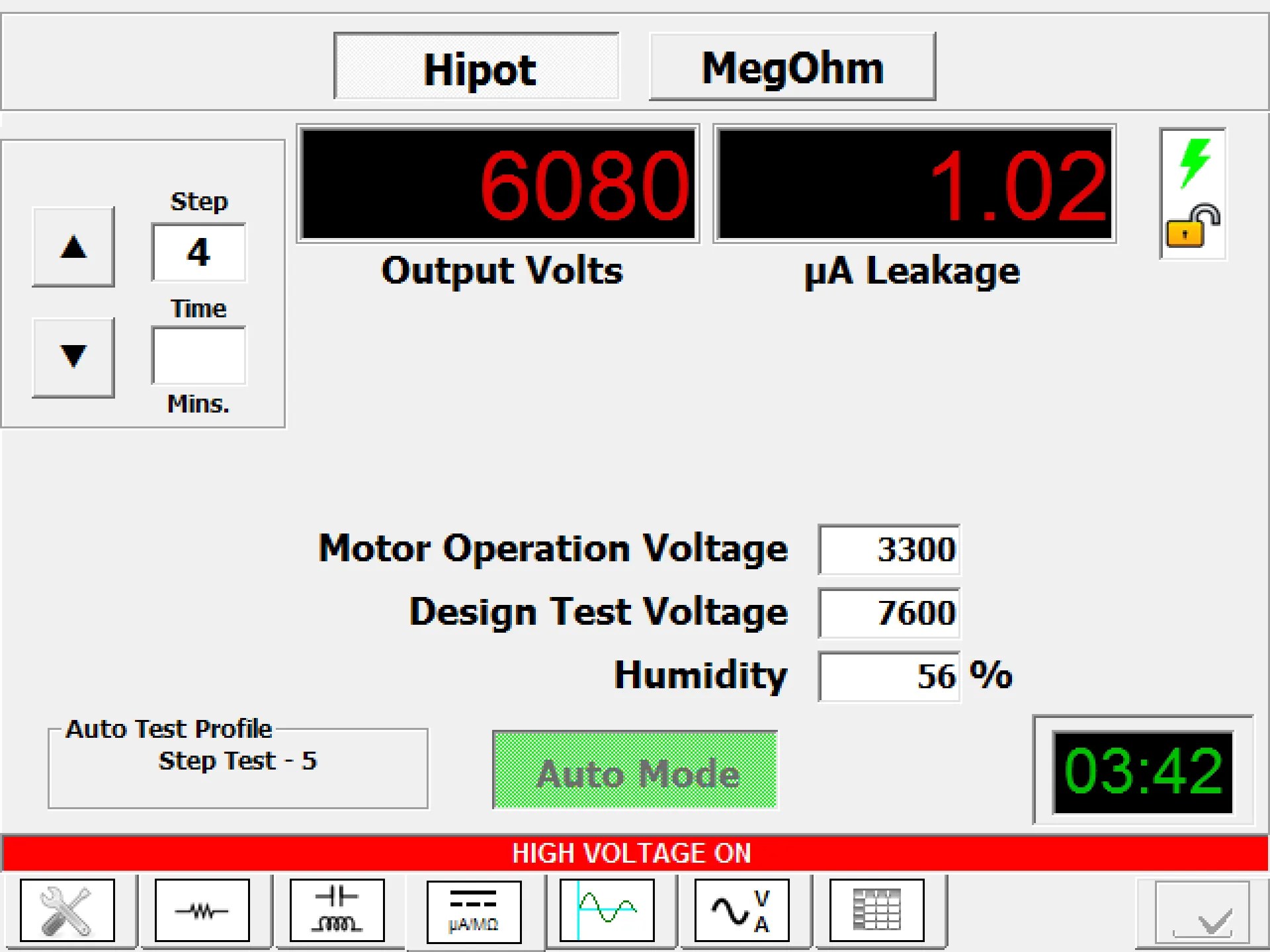

So how does this seemingly magical test work? In simple terms, a hipot tester applies a high voltage (much higher than the device's normal operating voltage) across the insulation for a specific duration. If the insulation holds up, meaning no current flows through it, the device passes. If current leaks, it signifies a weakness in the insulation, and the device fails the test.

The aim of a hipot test isn’t to destroy the insulation but to identify potential weaknesses before they become real-world hazards. It's like giving your electrical system a thorough health checkup, identifying hidden vulnerabilities that could otherwise go undetected.

The history of hipot testing goes back to the early days of electricity, evolving alongside our increasing reliance on electrical devices. Its importance has grown exponentially, becoming an indispensable part of manufacturing, maintenance, and safety protocols across industries.

One key issue related to hipot testing is determining the appropriate voltage and duration. Applying too much voltage can damage good insulation, while applying too little might not reveal existing flaws. Finding the right balance is crucial for effective and safe testing.

The benefits of implementing hipot testing are threefold: enhanced safety, improved product reliability, and reduced risk of legal liabilities.

A successful hipot testing program requires careful planning and execution. Start by defining the scope of testing, selecting the appropriate equipment, and establishing clear testing procedures. Documenting the results is essential for traceability and future analysis.

Challenges in hipot testing include dealing with complex equipment geometries and ensuring consistent test results. Solutions involve using specialized test probes and implementing automated testing procedures.

Advantages and Disadvantages of Hipot Testing

| Advantages | Disadvantages |

|---|---|

| Enhances electrical safety | Can potentially damage the equipment under test if not performed correctly |

| Improves product reliability | Requires specialized equipment and trained personnel |

| Reduces risk of legal liabilities | Can be time-consuming, especially for complex systems |

Best practices include using calibrated equipment, following manufacturer guidelines, and ensuring proper grounding.

Real-world examples include testing household appliances, medical devices, and industrial machinery.

Frequently asked questions often cover topics like testing voltage levels, test duration, and safety precautions.

Tips and tricks for effective hipot testing include careful setup, proper grounding, and meticulous record-keeping.

In conclusion, hipot testing serves a vital purpose in today's world, where electrical devices are deeply integrated into our lives. It acts as a crucial safety net, preventing potential electrical hazards and safeguarding both individuals and equipment. By understanding the principles and benefits of hipot testing, we can make informed decisions about product safety and contribute to a safer electrical environment for everyone. Its consistent application leads to greater confidence in the safety and reliability of electrical systems, preventing accidents and promoting peace of mind. Embracing best practices and staying informed about advancements in hipot testing techniques is key to maximizing its effectiveness and ensuring a secure electrical future. If you're dealing with electrical systems, understanding and implementing hipot testing is not just a good idea—it's a necessity.

Decoding social media theories

Unraveling the mystique a deep dive into white cat project anime

Nfl power rankings week deciphering the gridiron hierarchy