Unlocking the Circle: A Journey into Bolt Circle Measurement

From the grand sweep of planetary orbits to the intricate dance of electrons around an atom, circles hold a fundamental place in the architecture of our universe. In the realm of engineering and manufacturing, a specific circular arrangement, the bolt circle, plays a pivotal role in joining components, from car engines to towering wind turbines. Understanding how to determine a bolt circle's dimensions is essential for anyone working with machinery, construction, or even DIY projects. But how do we measure this crucial circular footprint?

The bolt circle, also known as the bolt hole circle or pitch circle diameter (PCD), defines the imaginary circle that passes through the center of each bolt hole. Accurately measuring the bolt circle ensures proper alignment, secure fastening, and the integrity of the assembled structure. Imagine a wheel, its bolts evenly spaced around the hub. An incorrect bolt circle measurement could lead to wobble, instability, and ultimately, failure. This seemingly simple measurement carries significant weight.

The historical origins of standardized bolt circles are intertwined with the rise of mass production and interchangeable parts. As manufacturing evolved, the need for consistent and accurate measurements became paramount. Bolt circles provided a standardized framework for component assembly, enabling efficiency and scalability. The ability to accurately determine bolt circle dimensions became a cornerstone of modern engineering.

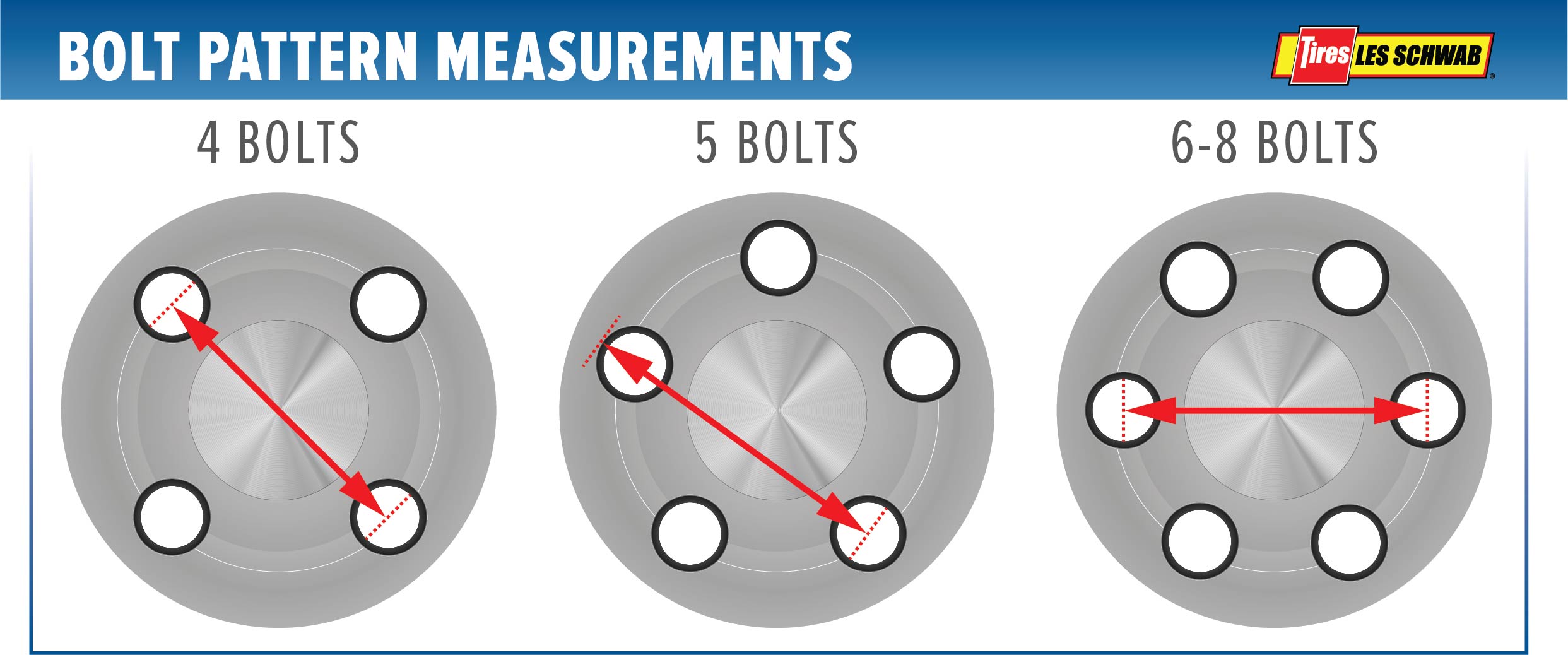

Several methods exist for measuring bolt circles, each tailored to different scenarios. For bolt circles with an even number of holes, measuring the distance between the centers of two opposite holes provides the diameter directly. With an odd number of holes, a bit more trigonometry is involved, requiring measurements between non-diametrically opposed holes and applying geometric formulas. The rise of digital calipers and other advanced measuring tools has simplified this process, allowing for greater precision and speed. However, understanding the underlying principles remains crucial.

Misinterpreting the bolt circle, using inaccurate tools, or applying incorrect formulas are common issues that can lead to assembly problems. A slight deviation in the bolt circle can throw off the entire alignment, leading to stress on the bolts, potential damage to the components, and ultimately, system failure. Therefore, mastering accurate bolt circle measurement is not just a matter of precision; it's a matter of ensuring safety and functionality.

One benefit of accurate bolt circle measurement is ensuring proper fit and function. Correctly measured bolt circles allow components to mate seamlessly, preventing stress and ensuring efficient load distribution. Another benefit is improved safety. Accurate measurements contribute to the structural integrity of the assembly, reducing the risk of failure and potential hazards. Lastly, proper bolt circle measurement saves time and resources, avoiding costly rework and replacements caused by incorrect initial measurements.

To measure a bolt circle with an even number of holes, simply measure across two opposite hole centers. For an odd number of holes, measure the distance between two non-diametrically opposite holes and use a bolt circle calculator or a formula involving trigonometry based on the number of holes. Ensure your measuring tools are calibrated and use appropriate techniques for precise measurements. Double-checking your measurements is always recommended.

Advantages and Disadvantages of Different Bolt Circle Measurement Methods

| Method | Advantages | Disadvantages |

|---|---|---|

| Direct Measurement (Even Holes) | Simple and fast | Only applicable to even number of holes |

| Trigonometric Calculation (Odd Holes) | Works for any number of holes | More complex, requires calculations |

Best Practices:

1. Use calibrated measuring tools.

2. Double-check your measurements.

3. Choose the appropriate measurement method based on the number of holes.

4. Ensure proper lighting and clear visibility.

5. Consult engineering drawings or specifications for precise bolt circle requirements.

FAQ:

1. What is a bolt circle? - The circle that passes through the center of all bolt holes.

2. Why is bolt circle measurement important? - Ensures proper alignment and secure fastening.

3. How do I measure a bolt circle with 3 holes? - Use a trigonometric calculation or a bolt circle calculator.

4. What tools are needed? - Calipers, rulers, or specialized bolt circle gauges.

5. What is PCD? - Pitch Circle Diameter, another term for bolt circle.

6. What happens if the bolt circle is measured incorrectly? - Can lead to assembly problems and component failure.

7. How can I improve the accuracy of my measurements? - Use calibrated tools and double-check your work.

8. Where can I find more information? - Machinist handbooks, engineering textbooks, and online resources.

Tips and Tricks: For enhanced accuracy, consider using a center finding tool to pinpoint the exact center of each hole. Document your measurements meticulously for future reference.

In conclusion, the seemingly simple act of measuring a bolt circle holds profound significance in the world of engineering and manufacturing. From ensuring the smooth rotation of a wheel to the structural integrity of a bridge, accurate bolt circle measurement underpins countless applications. By understanding the different methods, best practices, and potential challenges, we can unlock the power of the circle and ensure precise, reliable, and safe assembly. Mastering this fundamental skill empowers us to build, create, and innovate with confidence, knowing that even the smallest circle can hold the greatest strength. Take the time to familiarize yourself with the various techniques and invest in quality measuring tools. The precision you gain will pay dividends in the long run, ensuring the success of your projects and contributing to a world built on accuracy and reliability.

Farrow and ball ballroom blue a deep dive into the iconic paint

Transform your space with serene green blue gray paint

Udf carbon cto filters a deep dive